CLIMAVER® system is a solution for manufacture of HVAC pipelines and bends of glass wool panels. The product is self-supporting HVAC pipeline for distribution of treated air for the purpose of heating, ventilation and air conditioning.

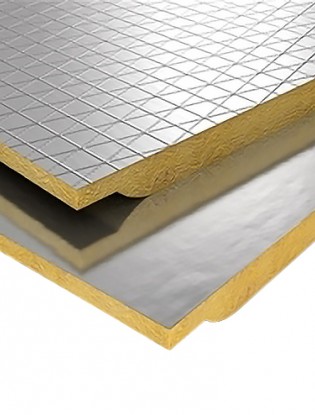

CLIMAVER® panel consists of an external surface layer, a core and an internal surface layer. The panel core is made of glass wool, thickness 25 or 40 mm. the external side of the panel is covered with aluminium film. The inside surface finish is represented either by another aluminium film or a resistant antibacterial fabric of glass fibre with high mechanical resistance. Both surface layers are reinforced with arming mesh of glass fibre.

The panels are used for manufacture of a straight air duct by straight line – bend method using special CLIMAVER® tools and accessories. Thanks to the manufacture of “pre-insulated” panels the pipeline assembly is quick and thus saves time and extra costs on site.

The CLIMAVER® system was designed to provide excellent thermal and acoustic properties and a high air-tightness level. These properties make the system energy-saving.

![[:cs]Pomocí nářadí CLIMAVER® vytvoříme stupňovou drážku[:en]Make a stepped groove with CLIMAVER® tool[:de]Mit dem CLIMAVER® werkzeug eine stufenartige rille bilden[:ru]ИСПОЛЬЗУЯ ИНСТРУМЕНТЫ CLIMAVER®, СОЗДАЙТЕ СТУПЕНЧАТЫЙ ПАЗ[:]](https://arax.cz/wp-content/uploads/2019/05/5956.jpg)

![[:cs]Odstraníme vyříznutý kus skelné vlny z drážky[:en]Remove the cut off glass fibre from the groove[:de]Das ausgeschnittene stück Glaswolle aus der rille Entfernen[:ru]УДАЛИТЕ ВЫРЕЗАННУЮ ЧАСТЬ СТЕКЛОВАТЫ ИЗ ПАЗА[:]](https://arax.cz/wp-content/uploads/2019/05/5968.jpg)

![[:cs]Jednoduše složíme vzduchový kanál[:en]Assemble the air duct[:de]Den Lüftungskanal einfach zusammenfalten[:ru]СЛОЖИТЕ ВОЗДУХОВОД[:]](https://arax.cz/wp-content/uploads/2019/05/5979.jpg)

![[:cs]Zajistíme spoj sponkovačkou CLIMAVER®[:en]Use CLIMAVER® stapler to join[:de]Die Verbindung mit dem CLIMAVER® Tacker sichern[:ru]ЗАКРЕПИТЕ СОЕДИНЕНИЕ С ПОМОЩЬЮ СКОБОЗАБИВНОГО ПИСТОЛЕТА CLIMAVER®[:]](https://arax.cz/wp-content/uploads/2019/05/5987.jpg)

![[:cs]Spoj vzduchotěsně slepíme lepící páskou CLIMAVER®[:en]Use CLIMAVER® sealing tape to make the joint air-tight[:de]Die Verbindung luftdicht mit dem CLIMAVER® Klebeband zusammenkleben[:ru]ГЕРМЕТИЧНО СКЛЕЙТЕ СОЕДИНЕНИЕ С ПОМОЩЬЮ КЛЕЙКОЙ ЛЕНТЫ CLIMAVER®[:]](https://arax.cz/wp-content/uploads/2019/05/6000.jpg)

![[:cs]Pro vytvoření těsného spoje zahladíme pásku CLIMAVER®[:en]To create a sealed joint smoothen the CLIMAVER® tape[:de]Für die Schaffung einer dichten Verbindung das CLIMAVER® band glätten[:ru]ДЛЯ СОЗДАНИЯ ГЕРМЕТИЧНОГО СОЕДИНЕНИЯ, ЗАГЛАДЬТЕ ЛЕНТУ CLIMAVER®[:]](https://arax.cz/wp-content/uploads/2019/05/6004.jpg)

![[:cs]Hotový rovný úsek VZT potrubí[:en]Finished HVAC pipeline straight section[:de]Fertiger ebener Abschnitt des Lüftungskanals[:ru]ГОТОВАЯ РОВНАЯ ЧАСТЬ ВЕНТИЛЯЦИОННОГО ТРУБОПРОВОДА[:]](https://arax.cz/wp-content/uploads/2019/05/6013.jpg)

![[:cs]climaver-plus-wide[:]](https://arax.cz/wp-content/uploads/2019/05/climaver-plus-wide.jpg)

![[:cs]climaver-neto-wide[:]](https://arax.cz/wp-content/uploads/2019/05/climaver-neto-wide.jpg)

![[:en]pressure-loss[:]](https://arax.cz/wp-content/uploads/2019/05/pressure-loss.png)

![[:en]air-leak[:]](https://arax.cz/wp-content/uploads/2019/05/air-leak.png)

![[:en]sound-absorbtion[:de]Schallabsorption (αw)[:] [:de]Schallabsorption (αw)[:ru]Поглощаемость звука (αw)[:]](https://arax.cz/wp-content/uploads/2019/05/sound-absorbtion.png)

![[:cs]ikona-bsi[:]](https://arax.cz/wp-content/uploads/2019/05/ikona-bsi.png)

![[:cs]ikona-euceb[:]](https://arax.cz/wp-content/uploads/2019/05/ikona-euceb.png)

![[:cs]certifikace[:]](https://arax.cz/wp-content/uploads/2019/05/certifikace.jpg)

![[:cs]potrubi[:]](https://arax.cz/wp-content/uploads/2019/05/potrubi.jpg)